Phase diagrams

Crystallization from solution has been used as a purification method since the dawn of civilization. Despite this fact, it is still one of the most important techniques for obtaining compounds with a high degree of purity. The method is equally used in research laboratories and in industry. The applications range from large scale production or recovery of solid materials, to more specialized goals, such as the isolation of new substances, or the selective preparation of different crystalline phases (polymorphs) or solvates of a given compound. The synthesis of stable polymorphs and solvates currently has, for example, a strong impact in the pharmaceutical industry, since it provides a means to alter the properties of an active principle (e.g. the solubility and dissolution rate, which often determine the bioavailability) in view of an application, without changing the molecule involved. The control of the crystallization kinetics also allows, to a certain extent, the production of materials with optimum crystal sizes and size distributions for further use or processing.

Thermal analysis is a powerful method to study crystallization from solution. The designation thermal analysis generally applies to techniques where physical or chemical changes in a given sample are monitored as a function of a programmed temperature-time variation. Thermal analytical methods are, therefore, very convenient to evaluate how the onsets of crystallization on cooling (limit of supersaturation), or of complete dissolution on heating (limit of solubility) depend on the cooling or heating rates, and to provide information about the kinetics of crystal nucleation and growth.

A primary result of these studies is the identification of the metastable zone width (MZW, Figure 1). Because supersaturation (a solution is said to be supersaturated at a given temperature, if it contains a larger concentration of dissolved solid than that corresponding to the equilibrium saturation at that temperature) is an essential requirement for the crystallization to occur, the values of nucleation temperature, T

Figure 1. Saturation-supersaturation diagram showing the stable, metastable, and labile zones for the crystallization of a solid from solution. The solid line represents the equilibrium solubility curve and the dashed line represents the maximum supersaturation or nucleation curve. The separation of the two curves represents the metastable zone width.

Once the MZW is known for a convenient set of experimental conditions (cooling rate, stirring, etc.), it is possible to devise a crystallization protocol where a constant supersaturation is approximately maintained throughout the cooling, leading to nearly constant nucleation and crystal growth rates. This allows some control of the nucleation and crystal growth kinetics and, therefore, of the optimum crystal size and size distribution, which, as mentioned above, may be important for further use or processing of the obtained product. Furthermore, the existence of curvature changes in the solubility curve or in the nucleation curve can indicate the formation of different crystalline phases, making this method interesting for the delineation of phase diagrams and polymorph screening.

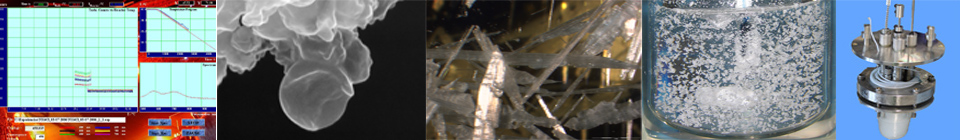

One major tool used at the Molecular Energetics Group for the thermoanalytical investigation of solution crystallization processes, is the in-house developed CB1 reactor. The apparatus can be programmed to automatically perform sequences of heating and cooling ramps, and isothermal steps, while continuously monitoring the mixture inside the crystallization vessel, with temperature and turbidity probes. These allow the onsets of crystallization and complete dissolution of the solid to be detected. Programmed dilutions of the mixture under study can also be made, so that different compositions may be studied, and the solubility and supersturation curves determined within a desired range of the c-T diagram (Figure 1) from a single experiment. This experimental strategy is normally dubbed polythermal method [6,7].